Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

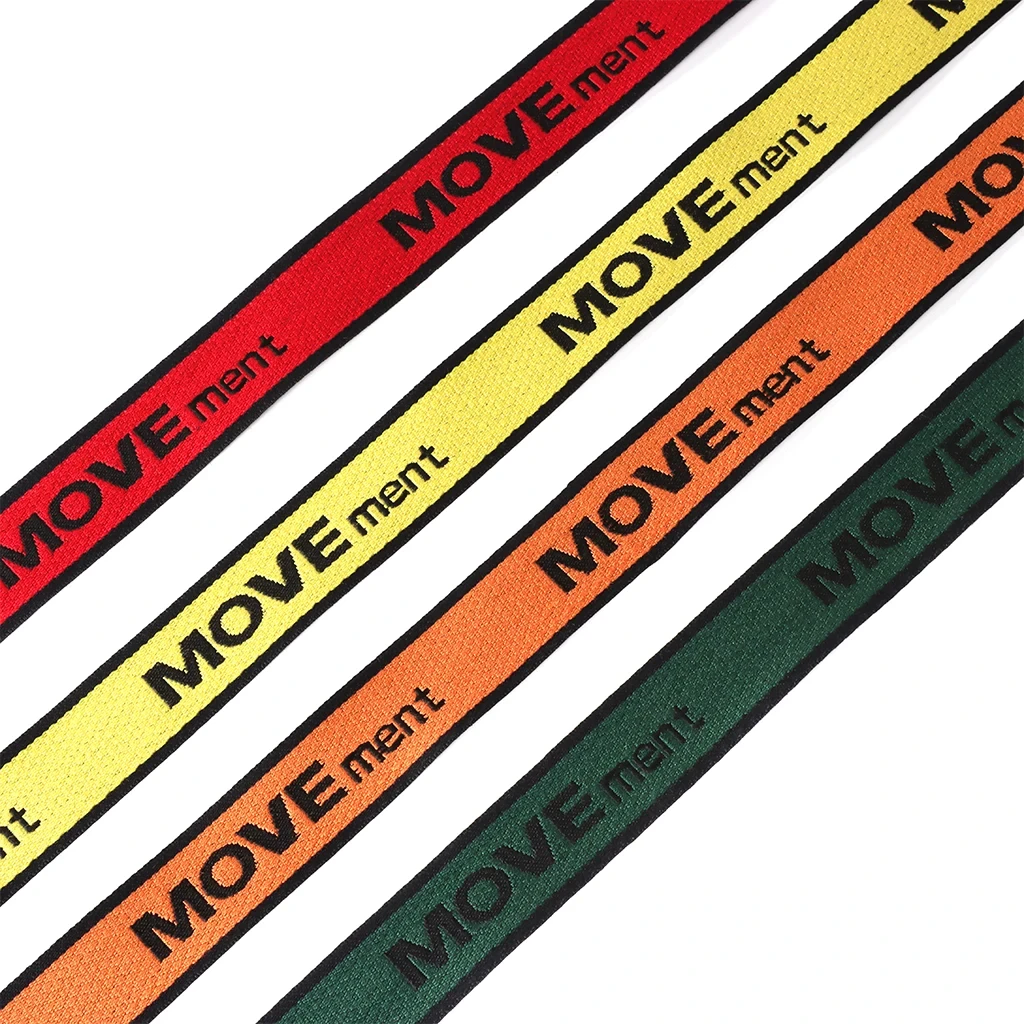

Introduction

When it comes to custom woven tape, one of the key considerations is the printing technique used to create the desired design or logo. The printing technique not only affects the visual appeal of the tape but also its durability and longevity. In this blog post, we will explore some of the common printing techniques used for custom woven tape.

Silk Screen Printing

Heat Transfer Printing

Heat transfer printing is another commonly used technique for custom woven tape. In this method, the design is first printed onto a special transfer paper using heat-sensitive inks. The transfer paper is then placed on the tape, and heat is applied, causing the ink to transfer from the paper to the tape.

Heat transfer printing allows for high-quality, full-colour designs with excellent clarity and detail. It is a versatile technique that can be used on various types of tape materials, including polyester and nylon. However, it is important to note that heat transfer printing may not be as durable as other printing techniques and may fade over time with repeated washing and use.

Digital Printing

Digital printing, also known as direct-to-garment printing, is a modern and advanced technique for printing on custom woven tape. It involves using specialised inkjet printers that directly apply the ink to the tape.

Sublimation Printing

Sublimation printing is a unique technique that involves transferring the design onto the tape using heat and pressure. The design is first printed onto a special sublimation paper using sublimation inks.

The paper is then placed on the tape, and heat and pressure are applied, causing the ink to vaporise and penetrate the tape fibres. As the tape cools, the ink solidifies, resulting in a permanent and vibrant design.

Sublimation printing offers excellent colour reproduction and allows for full-colour, high-resolution designs. It is particularly suitable for polyester-based tapes, as the ink bonds with the synthetic fibres, resulting in a durable and long-lasting print.

Conclusion

When it comes to custom woven tape, the printing technique used plays a crucial role in determining the final result. Silk screen printing, heat transfer printing, digital printing, and sublimation printing are some of the common techniques used. Each technique has its own advantages and considerations, such as colour vibrancy, durability, and cost. By understanding the different printing techniques available, you can make an informed decision and choose the one that best suits your needs and requirements for custom woven tape.